Technical data of Textile Machinery Accessories&Parts

A) Machining precision tolerance: +/-0.01mm B) Roughness value: Ra0.4, Ra0.8, Ra1.6, Ra3.2 C) Lead time: Within 30 days normally, according to order quantity. D) Minimum Order: 1 PCS. E) Transporting: UPS, DHL, FEDEX; BY SEA OR BY AIR on your requirement.Various material of Textile Machinery Accessories&Parts

Stainless steel: SS304, SS304L, SS316, SS316L, SS303, SS630 Carbon steel: 35CrMo, 42CrMo, ST-52, Ck45, alloy steel; ST-37, S235JR, C20, C45, 1213, 12L14 carbon steel; Cast steel: GS52 Cast iron: GG20, GG40,GGG40, GGG60 Brass alloy: C36000, C27400,C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2 Aluminum alloy: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A. Plastic: DERLIN, Nylon, Teflon, POM, PMMA, PEEK, PTFEMaterial of Textile Machinery Accessories&Parts

Textile machinery accessories&parts include parts of knitting machine, sewing machine, spinning machine etc.Advantages of GUOSHI Textile Machinery Accessories&Parts

Guoshi is equipped with advanced inspection machine, before shipping, to ensure that all products are machined within the tolerance. – High production capacity and competitive price – All Textile Machinery Accessories&Parts are subject to strict quality inspections – OEM express service can ensure that you receive the requested products, support DDP, CIF, FOB and other delivery terms to ensure that customers can receive the goods safely. – Machined according to your CAD and 3D drawings or sample. – Located in Pudong district, Shanghai, convenient for customer visit and shipment. – Professional machining experiences for more than 10 years on Textile Machinery Accessories&Parts.

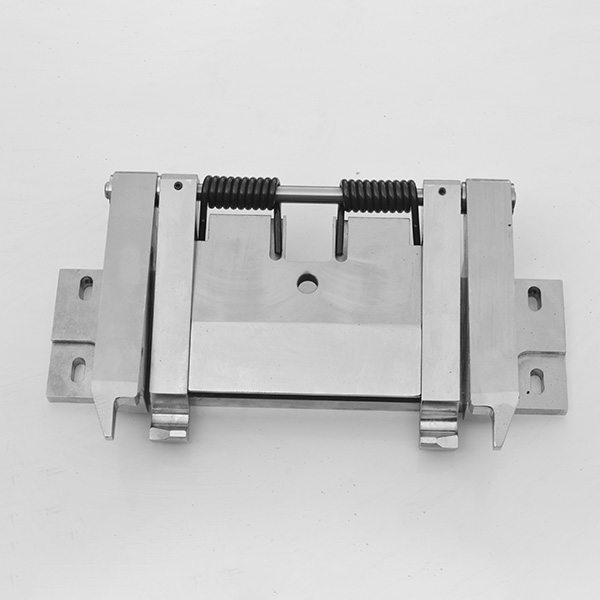

Carbon steel cast parts for textile machine

Carbon steel cnc lathing and threaded parts

Carbon steel cnc lathing parts for textile machine

Developing of Textile Machinery

Textile manufacturing is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most important natural fibre, so is treated in depth. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. It include spinning-yarn manufacturing, weaving-fabric manufacturing, knitting-fabric manufacturing, finishiningprocessing of textiles.