Introduction of Aluminum alloy parts

Aluminum alloy are alloy in which aluminum(AL)is the predominant metal. The typical alloy elements are copper, magnesium,manganess, silicon and any zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories of heat treatable and non heat treatable.Engineering use of Aluminum alloy parts

Aluminum alloy is very common in our life, our doors and windows, bed, cooking utensils,tableware,bicycles,cars etc. Containing aluminum alloy. Ordinary aluminum alloy in the application of the life. Aluminum alloys with a wide range of properties are informs the engineering in srtuctures. The selecting the right alloy for given application entails considerations of its tensile strength, density, ductility,formability, workability, weldability and corrosion to hold. Aluminum alloy are used extensively in aircraft due to the high strength to weight ratio.Aluminum alloys versus of steel

Aluminium alloys typically have an elastic modulus of about 70GPa, which is about one third of the elastic modulus of most kinds of steel and steel alloys. Therefore, for a given load, a component or unit made of an aluminium alloy will expensive a greater elastic deformation than a steel part of the identical size of shape. Light quality, high strength,corrosion,resistance,easy forming,welding. Alloys composed mostly of aluminum have been very important in aerospace manufacturing since the introduction of metal skinned aircraft. Aluminum magnesium alloys are both lighter than other aluminum alloys and much less flammable than alloy that contain a very high percentage of magnesium.Heat sensitivity considerations about Aluminum alloy parts

Often, the metal’s sensitivity to heat also be considered, even a relatively routine workshop procedure involving heating is complicated by the fact that aluminum, unlike steel, will melt without first glowing red.

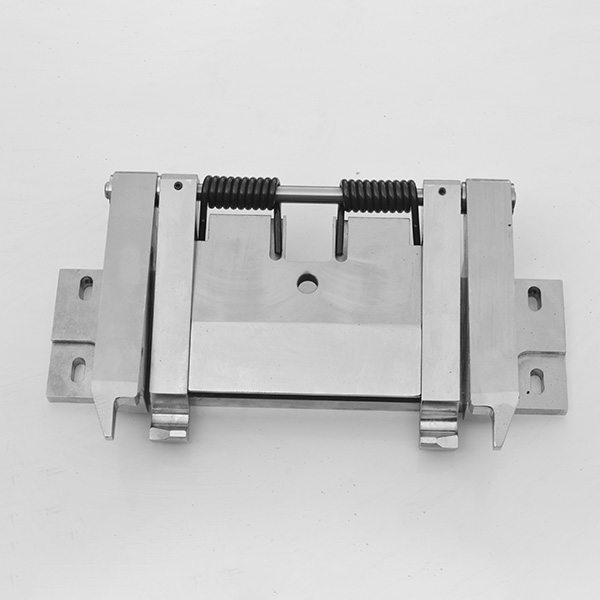

AlMg0.7Si Aluminum cover parts

AlMg1SiCu Aluminum cnc turning parts

Aluminum turning rod parts with knurling

EN AW-2024 Aluminum press casting and threading aluminum parts

EN AW-6061 Aluminum flat bar milling

EN AW-6063A Aluminum hexgon rod parts machining

Maintenance of Aluminum alloy parts

Aluminum alloy surfaces will keep their apparent shine in a dry environment due to the formation of a clear, protective layer of aluminum oxide. In a wet environment, galvanic corrosion can occur when an aluminum alloy is placed in electrical contact with other metals with more negative corrosion potentials than aluminum.Application of Aluminum alloy parts

Main alloying elements are copper, silicon, magnesium, zinc, manganese, secondary alloying elements are nickle, iron, titanium, chromium, lithium,etc. Aluminum alloy is the most widely used in industry of non ferrous metal structural materials in aviation, aerospace, automotive, machinery manufacturing, shipping and have been extensively applied in chemical industry. Aluminum alloy density is low, but the intensity is high.Aluminum alloy classification

The alloys that are applied to die casting are now made up of aluminum alloy. It has the physical properties of light and good corrosion resistance and mechanical properties, and good heat conduction. Aluminum alloy can be divided into processing and casting materials, and can be classified into two kinds:heat-treated aluminum alloy and non heat treated aluminum alloy materials in the processing materials. Die casting aluminum alloy is the casting material, and the aluminum alloy which is used in general is not suitable for heat treatment because it is processed into products through die casting process. Aluminum silicon series The general aluminum alloy, such ADC1, applies to large, thin walls and complex shapes. The content of silicon elements near eutectic point and make the casting molten liquidity is good, it has excellent castability, corrosion resistance, high thermal conductivity, thermal expansion and the proportion of less 2.65g/cm3,etc. However, it is not good to be brittle and brittle, and the anodic oxidation is not good. If the casting conditions are not suitable, the molten fluid is slow. Aluminium silicon copper ADC12 alloy is in Al-Si alloy add copper alloy element, is the most widely used the representation of the die casting aluminum alloy, its excellent castability and mechanical properties, but poor corrosion resistance. Aluminum-Silicon-Magnesium series ADC3 aluminum alloy is in Al-Si alloy adding alloy element such Mg,Fe,with excellent mechanical properties, corrosion resistance an good castability, but when the content of iron less than 1% easy adhesion with the metal mould, alloy is widely used. The other ADC5 and ADC 6 alloys, also known as aluminum-magnesium alloys, are more powerful, corrision resistant and machined, and are the best in aluminum alloy. However, due to the large amount of solidification and thermal expansion coefficient, the alloy casting is not good. A liquidity also poor, prone to sticking phenomenon and loss of metallic luster after grinding, so it is suitable for the anodic oxidation treatment, and other impurity such as iron, silicon and so on all affect the surface appearance. Different countries have different titles for the die-cast aluminum alloy, such as Axxx is the American model, ADCxx is the Japanese model, LMxx is the British model, YLxxx is the Chinese model. Surface treatment of die casting aluminum alloy parts The anodic oxidation. At the same time, it has functional and ornamental surface, and most anodized aluminum alloy is about 2-25um. High durability and anti-wear aluminum alloy castings have 25-75um surface thickness. Aluminum alloy oxide layer can be processed and developed. All kinds of colors are not conductive when it is oxidized, so they can be safely used in different parts of electrical appliances. Phosphide/chromium. Phosphatification is a useful non metal and thinner coating that forms a replacement layer on the metal surface through phosphorus compounds. It applies to steel, zinc alloy, aluminum alloy and other products, which can improve corrosion resistance and wear resistance. The membrane is currently the best resistant to the aluminum conversion film, so it can be treated as a single coating on the surface of the aluminum alloy. The micro-arc oxidation. Using high voltage on aluminum parts to make ceramic surface film, coating hardness and abrasion resistance is extremely high, and corrosion resistance and unique. The margin is better than the anode. The microarc membrane is formed by three groups: The first layer is a thin film attached to the surface of the aluminum, which is about 3 to 5um. The second layer is the main part of the membrane, which is about 150 to 250um. The main layer is high in hardness and porosity is small and denser is very high. The third layer is the last surface layer. This layer is relatively loose and rough, so it will usually be processed and removed use on the main layer. The alunina microarc oxidation is compared with anodic oxidation. Application of microarc oxidation technology: Aviation accessories: pneumatic components and sealing parts. Auto parts: piston nozzle Home supplies:faucet, electric iron. Electronic instruments:meters and electrical insulation accessories.